Choosing the right decoration method for custom hats shouldn't feel like guesswork. Whether you're ordering branded caps for your team, launching a retail line, or creating promotional giveaways, the decoration method you choose affects how your hats look, feel, and how long they last. This guide walks you through the four main options and shows you how hat construction, design details, and your specific needs determine which method works best. By the end, you won't even need to put a thinking cap on to figure out the right choice for your project.

Embroidery vs Printing: Which Is Best? (The Short Answer)

Embroidery is the gold standard for hats; it looks the most professional, lasts the longest, and works on any hat style, which is why you see it on everything from corporate golf caps to retail brands. The downside is it costs a bit more than other methods. Screen printing works well for structured hats and trucker styles with flat front panels, especially for single-color designs and larger orders, but it struggles with front seams and certain materials. DTF handles multi-color and photographic designs beautifully and stretches with flexible fabrics. Heat-applied patches offer a permanent alternative to embroidery with a distinct look. Your best choice depends on your hat type, design complexity, and whether you're outfitting a sales team or creating trade show giveaways.

Hat Decoration Methods

Embroidery stitches thread directly into the fabric, creating a dimensional, textured design. The process starts with digitizing your artwork into a stitch file that guides industrial machines to sew the design using high-quality polyester or rayon thread. Embroidery delivers the most premium appearance and withstands years of wear without fading or degrading—thread colors stay vibrant indefinitely because they're woven into the fabric rather than sitting on the surface.

Screen Printing pushes ink through mesh screens onto the hat's surface, with each color requiring a separate screen. The printed design passes through a heat tunnel to cure the ink, bonding it permanently to the fabric. This method works best on structured hats with flat, stable front panels where the screen can make consistent contact with the material. Screen printing delivers sharp, bold graphics at an economical cost for larger orders.

DTF (Direct-to-Film) prints your design onto a special transfer film with ink and adhesive, then heat presses it onto the hat in a single application. The film peels away after pressing, leaving a flexible, detailed design that stretches with the fabric. DTF handles unlimited colors and photographic detail without setup costs or minimum quantities, making it ideal for complex artwork and smaller runs.

Heat-Press Patches are pre-made decorative elements—available in embroidered, rubber, leather, and 3D styles—that bond permanently to hats using heat and pressure. These patches offer consistent branding across different hat types and create a premium look that rivals traditional embroidery. They work particularly well when you want a distinctive texture or raised effect that standard decoration methods can't achieve.

Factors to Consider

Structured vs Unstructured

Hat structure determines which decoration methods work best. Structured hats have a buckram backing—a stiffening material beneath the front panels—that keeps the crown firm and tall. This stable foundation makes them ideal for embroidery, screen printing, and patches since the surface doesn't collapse under pressure or stitching. Unstructured hats lack this backing, giving them a soft, relaxed shape that conforms to the head. For unstructured styles like dad hats, embroidery remains the top choice, followed by patches. DTF can work if the hat has relatively smooth seams, but the soft fabric makes screen printing challenging since the material shifts during application.

Number of Panels

Panel count directly impacts decoration options. Six-panel hats have a vertical seam running down the center front, creating a ridge that interferes with printing. Screen printing creates a visible gap in the design where the seam interrupts ink contact, and DTF prints may lift or wear prematurely at the seam line. For six-panel hats, stick with embroidery or patches that can straddle the seam without issues. Five-panel hats typically feature one large front panel with no center seam—think trucker hats—providing a smooth, continuous surface perfect for screen printing, DTF, and larger embroidered designs.

Materials

Fabric type limits or expands your decoration choices. Embroidery works on virtually any material—cotton, polyester, canvas, twill, wool blends, even performance fabrics. DTF transfers also adapt to most materials. Screen printing gets pickier: heavily textured fabrics like brushed canvas, denim, felt, and suede prevent proper ink contact, resulting in incomplete coverage. Some synthetic performance materials can't withstand the high curing temperatures screen printing requires. For knit beanies or any stretchy knit material, avoid screen printing and DTF entirely—embroidery and patches maintain their integrity as the fabric flexes.

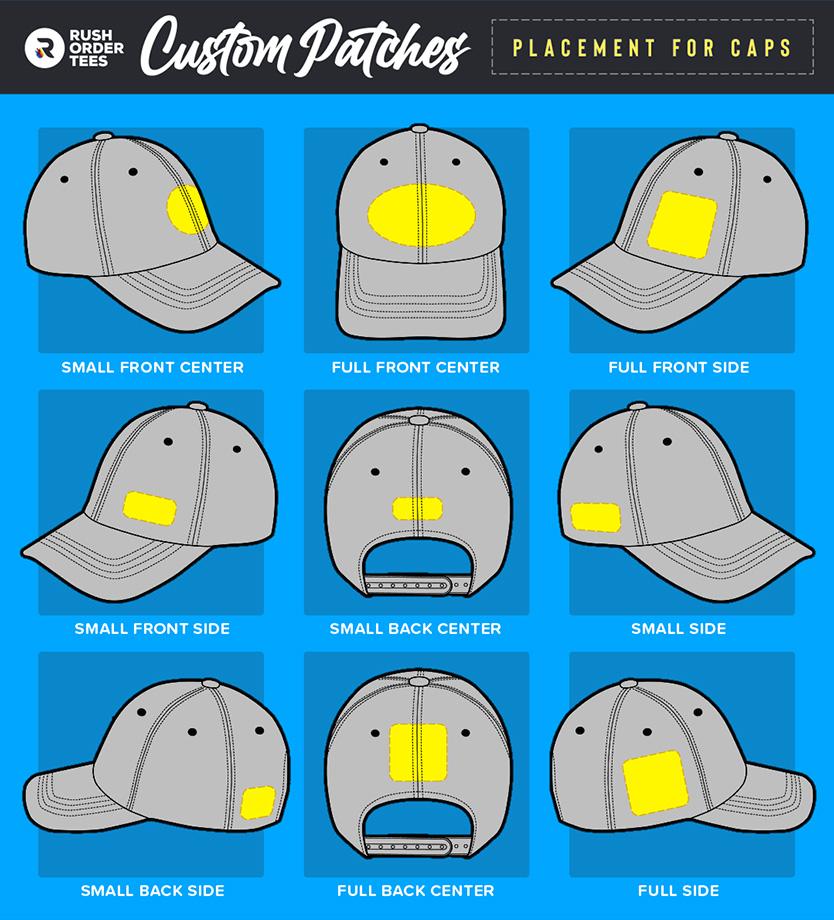

Print Location

Where you place your design affects which methods you can use. Standard front-center placement works for all methods, but alternative locations require consideration. Embroidery machines use hoops to stabilize fabric during stitching, which limits access to certain areas like the underside of brims or tight side panels. DTF offers more flexibility for unusual placements, like the brim of bucket hats, since it only needs flat heat press contact. Trucker hat mesh backs eliminate screen printing as an option, but embroidery and patches work fine. For fitted hats with solid backs, you gain decoration opportunities unavailable on snapback or adjustable styles where the closure hardware creates a large opening.

Closure Type

Hat closures—snapback, buckle, hook-and-loop (Velcro), or fitted—affect back decoration possibilities. Snapbacks, buckles, and Velcro closures create large openings that limit rear panel design size and placement. Fitted hats with elastic or no adjustment mechanism provide more continuous fabric on the back, allowing for centered logos or designs that would look awkward interrupted by closure hardware. Some brands put small logos or text on the back of adjustable hats positioned above or beside the closure, while others place designs on the side panels where closures don't interfere.

Plan Before You Buy

The smartest approach is deciding your decoration method at the same time as selecting hats. Matching hat construction to your decoration needs from the start prevents compatibility issues and ensures you get the results you're expecting.

Intended Use

Are you outfitting a corporate golf team or creating trade show giveaways? Selling retail merchandise or equipping a mechanic shop? Your hat's purpose determines how much to invest in decoration. Corporate branding, retail products, and employee uniforms justify embroidery's premium appearance and durability. Promotional giveaways and event swag work perfectly with screen printing's economical single-color approach. Match decoration quality to hat quality—don't screen print budget designs on premium hats, and don't waste elaborate embroidery on throwaway promotional items.

Design Complexity

Your logo's detail level narrows your decoration options. Simple, single-color designs open up screen printing as a cost-effective choice. Multi-color or photographic artwork requires DTF's unlimited color capabilities. Embroidery handles moderate complexity but requires simplification—fine lines, small text, and intricate details don't translate well to stitched designs. Review your artwork honestly before selecting hats: if your logo has gradients, photo elements, or more than four colors, you're looking at DTF or heavily modified embroidery.

Target Audience

Who's wearing these hats shapes your decoration decisions. Young, fashion-forward audiences gravitate toward flat-bill snapbacks and dad hats where DTF's detailed graphics shine. Traditional corporate environments expect the polished look of embroidery on structured baseball caps. Sporty demographics appreciate performance materials that work with any decoration method. Streetwear and casual audiences accept patches and alternative decoration styles that corporate buyers might reject. Consider whether your audience values premium presentation or trendy aesthetics.

Overall Budget

Balance hat cost with decoration investment for the best outcome. Premium hats deserve premium decoration—pair quality structured caps with embroidery or detailed DTF work. Budget hats match well with single-color screen printing or simple patches that keep total costs down. DTF and patches occupy the middle ground, working effectively across budget ranges without looking out of place. Calculate your per-piece budget including both the blank hat and decoration costs, then select the hat tier that allows your preferred decoration method without exceeding budget limits.

For those looking for the best premium hats, check out our Top 10 Picks for High-Quality Headwear.

Bonus Tips for Printing on Hats

- Keep designs small and simple. Maximum print area is around 4 inches wide, but 2-3 inch designs often look more professional and readable. Fine details, small text, and intricate elements get lost at hat decoration scale, so simplify your logo before ordering.

- Limit colors for screen printing. Single-color prints deliver the best value and cleanest results on hats. Each additional color increases setup costs with diminishing visual returns—stick to 2-3 colors maximum unless your logo absolutely requires more.

- Match your design to the hat colors. Use hat colors within your design for a cohesive, natural look that feels intentional rather than slapped on. Strong contrast ensures readability—black on light colors, white on dark colors—but consider complementary color combinations for a more sophisticated appearance.

- Prioritize visibility on safety hats. Black ink on fluorescent yellow (safety green) delivers maximum contrast and readability. For lighter orange hats, black works well, but darker orange and camo require bright white to maintain visibility in work environments.

- Add embroidery effects for premium results. Puff embroidery creates raised, dimensional logos that stand out on hats, while metallic thread adds upscale shine. These effects work exceptionally well for retail merchandise and corporate branding that needs to make a strong impression.

- Avoid oversized embroidery on soft hats. Large embroidered designs can distort the shape of unstructured dad hats and add uncomfortable stiffness to knit beanies. Keep embroidery modest on soft, flexible hats to maintain their intended fit and comfort.

- Test your design at actual size. Print your logo at the intended size on a home printer, cut it out, and tape it to a similar hat. This simple step reveals sizing issues, placement problems, and helps you experiment with alternative locations before committing to production.

- Consider the back and sides for fitted hats. Fitted hats without bulky closures offer clean back panels perfect for secondary logos or text. Side panels work for small accent designs that add visual interest without competing with front branding.

Get Your Custom Hats Right the First Time

Choosing between embroidery, screen printing, DTF, and patches doesn't have to be complicated once you understand how hat construction influences your options. Structured hats with five-panel fronts open up screen printing possibilities, while unstructured six-panel styles steer you toward embroidery or patches. Material and intended use narrow things further; performance fabrics and retail branding point to embroidery's premium durability, while promotional giveaways and budget orders favor screen printing's economical efficiency. Match your decoration method to your hat type from the start, and you'll avoid compatibility issues while getting the professional results your project deserves.

RushOrderTees brings over two decades of experience with custom hats to every order, with state-of-the-art embroidery machines and decoration technology that delivers consistent, sharp results across any hat style. Our in-house art team reviews every design for optimal decoration compatibility, offering free artwork optimization and expert guidance on hat selection, decoration methods, and design placement. With no minimum orders, fast turnaround options, and access to top hat brands, we'll help you create custom headwear that looks professional and gets worn—whether you're outfitting a small team or producing thousands of promotional pieces.

About the Author

A graduate of the Multimedia program at the University of the Arts in Philadelphia, Imri Merritt is an industry veteran with over 20 years of graphic design and color separations experience in the screen printing industry.