Custom pants have become the secret weapon for brands looking beyond t-shirts and hoodies. From work crews sporting embroidered joggers to fitness studios branded with sleek leggings, the pant game delivers professional polish and everyday wearability that keeps your logo visible longer. But here's the thing—the fabric weight, intended use, and placement strategy all determine which decoration method delivers lasting results without compromising comfort or durability.

What to Consider Before Customizing Pants

Before jumping into decoration methods, these key factors determine which approach delivers the best results for your specific project:

- Fabric Type and Weight - Cotton canvas and heavy fleece handle embroidery beautifully, while lightweight leggings and moisture-wicking activewear require heat transfer methods that move with stretch fabrics. Polyester blends in sweatpants and joggers offer versatility for multiple decoration techniques.

- Intended Use and Durability Requirements - Work uniforms and scrub pants face frequent washing and heavy use, demanding embroidery or durable screen printing. Casual women's sweatpants and joggers or comfort items like pajamas can use lighter decoration methods that prioritize comfort over industrial durability.

- Garment Construction and Seams - Flat surfaces work best for most decoration methods, while areas with seams, pleats, or elastic waistbands create challenges. Kids sweatpants often have smaller decoration areas that require scaled-down designs and careful placement consideration.

- Design Size and Complexity - Large, detailed artwork needs screen printing or DTF transfers, while simple logos work well with embroidery or heat transfer vinyl. Consider how the design will look proportional to the garment and whether it needs to remain readable when fabric stretches during wear.

- Budget and Quantity - Embroidery costs more per piece but offers premium durability, while screen printing becomes economical at higher quantities. Heat transfer methods work well for small runs or complex designs without setup charges.

Top Customization Methods for Pants

Each decoration technique brings distinct advantages depending on your fabric, design, and durability needs. Here's how the most popular methods perform on pants and where they deliver the best results.

Embroidery

- How It Works: Precision-stitched thread creates dimensional designs directly into the fabric using computerized embroidery machines. The process requires stabilizing backing material underneath the fabric to support the stitching.

- Best For: Premium workwear, fashion sweatpants, fleece joggers, and upscale athleisure where that dimensional, professional appearance justifies the higher cost. Perfect for corporate uniforms and branded merchandise where quality perception matters.

- Works Well On: Thick, stable fabrics like canvas work pants, heavy fleece sweatpants, cotton duck uniforms, and structured joggers. The fabric needs enough body to support dense stitching without puckering or distorting.

- Pros: Unmatched durability that outlasts the garment itself, premium three-dimensional appearance, excellent color retention, and professional look that elevates brand perception. Works beautifully on darker fabrics where other methods might struggle.

- Cons: Higher per-piece cost, limited design complexity, can feel stiff or scratchy against skin due to backing material. Avoid lightweight fabrics, stretch materials, or thin leggings where it may pucker, restrict movement, or create uncomfortable texture.

- Placement Ideas: Side hip area for maximum visibility, back pocket flap on cargo pants, outer thigh on structured joggers, or small logos on waistband areas. Keep designs under 4 inches wide to maintain comfort and garment drape.

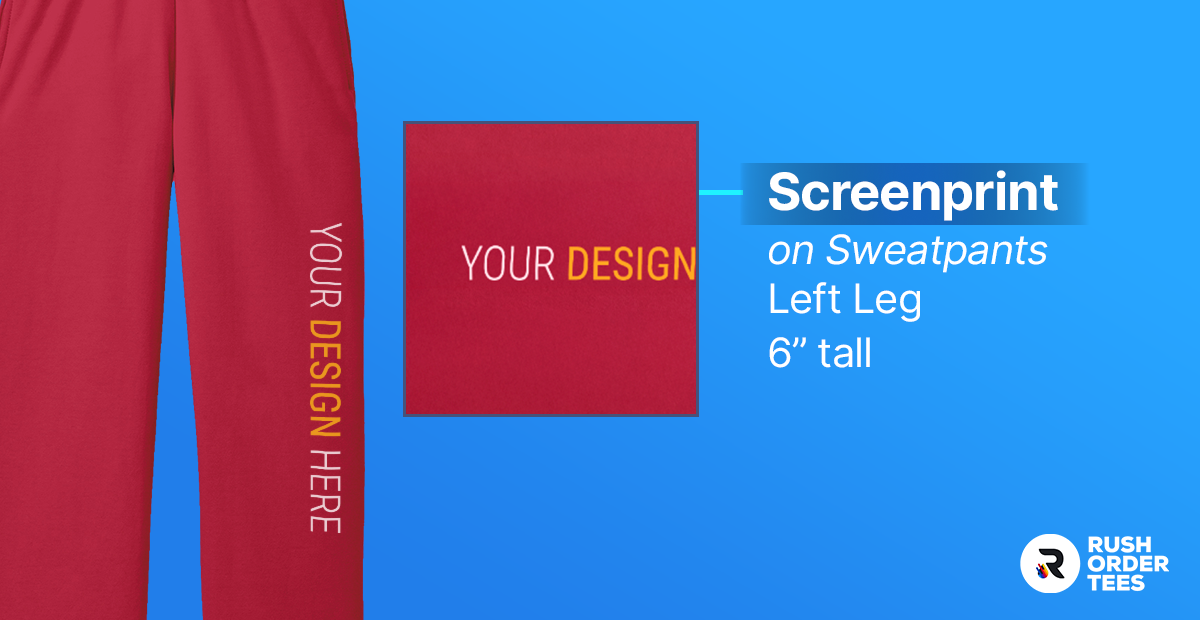

Screen Printing

- How It Works: Ink is pushed through mesh screens using a squeegee, with each color requiring a separate screen setup. The printed garments pass through a heat tunnel for final curing, creating a durable bond with the fabric surface.

- Best For: Larger print designs, single-color logos, high-volume orders where budget efficiency matters most. Essential when you need exact Pantone color matching or specialty inks like fluorescent, metallic, or puff effects that create unique visual impact.

- Works Well On: Smooth, flat fabric surfaces including cotton fleece, polyester blends, and structured materials. Works exceptionally well on sweatpants, uniform pants, and casual joggers with consistent fabric thickness.

- Pros: Extremely cost-effective at higher quantities, precise color matching capabilities, handles large designs beautifully, and offers specialty ink options like glow-in-the-dark or reflective effects. Excellent durability through repeated washing cycles.

- Cons: Setup costs make small quantities expensive, limited to simpler designs with distinct color separations. Large solid print areas can affect fabric breathability and natural drape, especially problematic on activewear and performance materials.

- Placement Ideas: Full back designs, large side panel graphics, or wraparound thigh prints work well. For activewear, break up large designs with negative space or consider strategic placement that doesn't interfere with movement and stretch zones.

DTF Transfers (Direct-to-Film)

- How It Works: Artwork is printed onto special transfer film using DTF inks and adhesive powder, then heat pressed onto the garment in a single application. The film peels away after pressing, leaving a flexible, detailed design bonded to the fabric surface.

- Best For: Colorful or detailed photographic designs, smooth gradients, crisp edges, and intricate artwork that other methods can't handle. Perfect when you need unlimited colors without setup charges or have complex logos with fine detail work.

- Works Well On: Any fabric type including lightweight materials, stretch fabrics, performance wear, cotton blends, and even challenging surfaces like moisture-wicking activewear. Particularly excellent on materials where embroidery would pucker or screen printing might not adhere properly.

- Pros: Excellent durability and stretch capabilities, unlimited color reproduction, works on any fabric type, no minimum quantities required, and maintains fabric flexibility. Superior detail reproduction with smooth gradients and photographic quality results.

- Cons: Higher per-piece cost than screen printing on large orders, can create a thin layer that may affect breathability on large solid designs. Not quite as premium-looking as embroidery for upscale applications.

- Placement Ideas: Works anywhere on pants including curved areas, stretch zones, and over seams. Ideal for side panels, outer thigh placements, or back pocket areas. For lighter weight materials, avoid large surface area designs to maintain comfort and breathability.

Heat Transfer Vinyl (HTV)

- How It Works: Vinyl material with adhesive backing is cut to design specifications using a plotter, then heat pressed onto the garment. The transfer vinyl bonds to the fabric surface under heat and pressure, creating a raised design layer.

- Best For: Traditional team wear and athletic applications where specialty colors matter more than premium feel. Still cost-effective for simple designs, numbers, or names when DTF pricing doesn't make sense for your project.

- Works Well On: Cotton blends, fleece, and structured fabrics that can handle the heat press process. Works best on garments with flat, smooth surfaces where the vinyl can make full contact during application.

- Pros: Access to specialty colors like fluorescent, glitter, metallic, reflective, and glow-in-the-dark options that other methods can't match. Can be more cost-effective than DTF for simple designs, especially single-color applications or small quantities.

- Cons: Heavy feel that can affect garment drape and comfort, prone to cracking and peeling over time, edges can lift with repeated washing and wear. Creates a thick, plastic-like layer that doesn't breathe or stretch with the fabric.

- Placement Ideas: Best on areas with minimal stretch and movement - back panels, side hip areas, or front chest placements. Avoid high-flex zones like knee areas or waistbands where the vinyl is more likely to crack or separate from the fabric.

Sublimation (Dye Sublimation)

- How It Works: Special sublimation inks are printed onto transfer paper, then heat pressed onto the garment. The inks skip the liquid phase and turn directly into gas, bonding permanently with polyester fibers at the molecular level.

- Best For: All-over print effects, complex photographic designs, smooth gradients, and intricate artwork requiring unlimited color reproduction. Perfect for performance wear, activewear, and fashion-forward designs where visual impact matters most.

- Works Well On: 100% polyester fabrics and high-polyester blends only. Requires white or very light-colored garments for proper color reproduction - the lighter the base fabric, the more vibrant the final result.

- Pros: Creates smooth gradients and photographic detail that other methods can't match, adds no weight or texture to the garment so drape and breathability remain completely unaffected. Extremely durable and permanent - the design becomes part of the fabric itself.

- Cons: Generally more expensive than other decoration methods, limited to polyester materials only, requires white or light-colored base garments for optimal results. Dark or cotton fabrics simply won't work with this process.

- Placement Ideas: Excels at full-panel designs, wraparound graphics, or edge-to-edge coverage that would be impossible with other methods. Perfect for performance leggings with allover patterns, activewear with complex geometric designs, or fashion joggers with photographic elements.

Patches (Heat Transfer DTF Patches)

- How It Works: DTF custom patches are printed and pressed onto release paper, then cut to specific shapes and applied to garments using a heat press. The patches can be designed to mimic various textures including embroidery, rubber, leather, or faux leather finishes.

- Best For: Small additional upscale branding, accent pieces, or when you want consistent branding across multiple garment types. Perfect for adding premium touches to structured workwear, uniform programs, or fashion collections requiring sophisticated details.

- Works Well On: Structured areas like jacket chests, shirt pockets, cargo flaps, or reinforced zones that can support the patch weight. Ideal for heavier fabrics like canvas, duck cloth, fleece, and substantial cotton blends.

- Pros: Excellent alternative to embroidery with similar visual impact, can replicate leather or rubber textures that other methods can't achieve, provides consistent branding across different garment types, and offers premium appearance at lower cost than actual embroidery.

- Cons: Can be too heavy for lightweight or stretch garments, may interfere with activewear performance and flexibility, requires flat application areas, and can feel stiff compared to other decoration methods.

- Placement Ideas: Back pocket areas, side hip structured zones, bottom hem corners for subtle branding, cargo pocket flaps, or waistband areas where they won't interfere with movement. Avoid stretch zones and high-flex areas on performance pants where patches might restrict movement or separate from the fabric.

Direct-to-Garment (DTG)

- How It Works: Specially formulated inks are applied directly onto fabric using inkjet printing technology, similar to a desktop printer but designed for textiles. The garment is pre-treated, printed, and then cured with heat to set the design.

- Best For: Cotton fleece loungewear, casual sweatpants, or comfort-focused pants where the softer hand feel outweighs durability concerns. Works well for detailed designs on lighter-duty garments that won't face heavy washing or wear.

- Works Well On: Cotton and cotton-polyester blends only - typically works best on 100% cotton or blends with high cotton content. Requires smooth, flat fabric surfaces for optimal print quality and ink absorption.

- Pros: Creates a lighter print with softer hand feel compared to screen printing or DTF, maintains better fabric drape and breathability since the ink absorbs into the fibers rather than sitting on top. Offers excellent detail reproduction for complex designs.

- Cons: Less durable than other methods and prone to fading over time, doesn't achieve the crisp edges that DTF delivers, limited to cotton and cotton-blend materials only. Generally falling out of favor as DTF technology improves and becomes more accessible.

- Placement Ideas: Best for front or back panels on casual joggers, lounge pants, or pajama bottoms where comfort matters more than longevity. Avoid high-wear areas since the print may fade faster than other decoration methods with repeated washing and use.

Where to Place Logos or Designs on Custom Pants

Unlike shirts with their standard chest and back locations, pants offer unique placement opportunities that balance visibility with functionality. The key is choosing spots that showcase your brand without interfering with comfort, movement, or the garment's intended use.

Outer Thigh

The outer thigh placement sits on the front of the left leg, typically starting at the crotch line and extending down toward the knee area. This highly visible location accommodates designs averaging 5x5 inches, though you can go smaller for subtle branding or larger for bold statements. The outer thigh works exceptionally well for athletic wear, joggers, and casual pants where the logo becomes part of the garment's design language.

This placement delivers strong brand visibility during movement and works particularly well with screen printing and DTF transfers that can handle fabric stretch. Just consider the wearer's activities—logos here face more wear from sitting, rubbing against surfaces, or contact with equipment, making durability crucial when selecting decoration methods.

Side Hip

The side hip offers an alternative placement that works particularly well on garments without side seams, creating a cleaner application surface for decoration. This location provides excellent visibility while remaining functional for most activities, making it popular for fashion-forward joggers and structured workwear. When working with pants that do have side seams, DTF transfers perform much better than screen printing since they conform better to uneven surfaces.

The side hip placement strikes a nice balance between subtlety and impact, offering brand visibility without the high-wear concerns of outer thigh positioning. Consider the garment's intended use and whether belts or equipment might cover or interfere with the logo placement—this location works best when it stays visible during normal wear.

The pocket placement encompasses both back pockets on traditional pants and cargo pockets on utility wear, making it one of the most versatile branding locations for workwear and casual pants. This area typically accommodates designs up to 3-4 inches wide, though you'll need to maintain at least an inch margin from all pocket seams. The pocket location works especially well on structured pants where the pocket provides a defined canvas for decoration.

Embroidery excels in this location, creating that upscale, professional look that's particularly popular on work uniforms and fashion joggers. The pocket placement offers excellent durability since it's naturally reinforced, and the branding feels intentional rather than added-on. Just ensure your decoration doesn't interfere with actual pocket functionality if users need access.

Calf or Lower Leg

The calf or lower leg represents a more uncommon placement that's gaining traction with fashion-forward brands looking to make a distinctive statement. This placement typically sits on the side or back of the lower leg, offering an unexpected branding opportunity that catches attention during movement while remaining subtle when stationary. The location works well with smaller designs and is especially effective with DTF transfers that can conform to the leg's natural curves.

Fashion brands particularly favor this location for creating unique design elements on joggers, leggings, and contemporary sweatpants where the logo becomes part of the garment's overall aesthetic. However, this placement faces higher wear from boots, socks, and general leg movement, so choose durable decoration methods—it's better suited for lifestyle wear than heavy-duty workwear applications.

Full Leg

The full leg placement extends vertically down the side of the leg, typically measuring around 4 inches wide by 16 inches high, creating a dramatic branding opportunity for team names, elongated logos, or creative fashion statements. This location usually runs along the outer seam but can be positioned front-facing for maximum visibility, making it popular with athletic teams and fashion brands seeking bold visual impact. Screen printing and DTF are the primary decoration methods for this placement.

To minimize comfort issues from large solid designs affecting breathability and fabric drape, consider limiting the actual surface area of your design—use outlined lettering instead of solid fills, incorporate negative space, or break up large elements. This placement demands careful consideration of the wearer's activities since such extensive decoration is more prone to wear, stretching, and potential damage from equipment or repeated washing.

Waistband

The waistband placement runs across the back, typically in the upper buttocks area below any elastic waistband construction. This location works well for slogans, messages, or website URLs rather than traditional logos, offering space for text-based designs that wouldn't fit elsewhere. Keep designs low-profile since anything taller than a few inches will get compressed and potentially damaged when sitting.

This is the least refined placement option and can appear more casual or even juvenile depending on execution, making it better suited for recreational wear, team spirit items, or promotional giveaways rather than professional uniforms. The waistband area faces significant wear from belts, sitting, and general movement, so choose decoration methods and messaging carefully—this works best for fun, casual branding rather than sophisticated corporate identity.

Customization Do's & Don'ts

- DO test on sample pants before bulk production. Always order a sample garment to test your exact decoration method, placement, and design before committing to a large order. What looks perfect on screen might not translate well to the actual fabric, especially with stretch materials or textured surfaces. Testing helps you catch potential issues like puckering, color bleeding, or placement problems that could affect the entire order.

- DO consider stretch in athletic wear. Performance pants and activewear require special attention since some decoration methods may crack, shift, or restrict movement during wear. DTF transfers and patches designed for stretch fabrics work better than rigid screen printing or dense embroidery on high-flex areas. Always account for how the fabric moves and stretches when choosing both decoration method and placement location.

- DO match decoration durability to garment use. Workwear and uniforms facing frequent washing need embroidery or DTF transfers that can withstand industrial laundering, while casual joggers or lounge pants can use lighter decoration methods. Consider the garment's intended lifespan and washing frequency when selecting decoration techniques - there's no point using premium embroidery on disposable promotional items or choosing budget screen printing for long-term uniforms.

- DON'T place logos over seams, pleats, or zippers. These construction details create uneven surfaces that interfere with proper decoration adhesion and can cause puckering, distortion, or premature failure. Seams and pleats also create stress points where decoration is more likely to crack or separate from the fabric. Always plan placement on flat, stable areas of the garment for best results.

- DON'T use embroidery on ultralight fabrics. Lightweight materials like thin leggings, moisture-wicking shorts, or delicate lounge pants lack the structure to support dense embroidery stitching. The weight and backing material required for embroidery can cause puckering, distortion, or an uncomfortable feel against the skin. Choose DTF transfers or other lightweight decoration methods for these applications.

- DON'T ignore fabric stretch zones when planning designs. High-flex areas like knee zones, waistbands, and hip areas require decoration methods that move with the fabric. Rigid screen printing or HTV in these locations will crack and peel over time, while oversized designs can restrict natural movement and comfort. Consider fabric behavior during normal wear when finalizing decoration placement and size.

Find Your Perfect Pants & Print Combination

The right decoration method for custom logo pants depends on fabric, use case, and branding goals, but you don't have to navigate these choices alone. From heavyweight sweatpants that can afford embroidery's durability to performance leggings requiring DTF's flexibility, each combination serves a specific purpose. Understanding these fundamentals helps you make informed decisions, but the real magic happens when you match the perfect garment to the ideal decoration method.

At RushOrderTees, we've spent decades mastering the art of customizing pants of all kinds. Our team knows which decoration methods work best on different fabrics, how placement affects durability, and where to position your design for maximum impact without compromising comfort. We can guide you toward the perfect combination of garment and decoration method that delivers lasting results your team will actually want to wear.

About the Author

A graduate of the Multimedia program at the University of the Arts in Philadelphia, Imri Merritt is an industry veteran with over 20 years of graphic design and color separations experience in the screen printing industry.